Improves services through technology to

become the best gearbox operation and

maintenance enterprise in the world

In the gear transmission process, situations such as broken gears, tooth surface damage, and bearing damage may occur, resulting in the loss of its normal ability to work. The above phenomena are collectively referred to as failure phenomena. The failure analysis is to carry out a series of detections and analyses of these phenomena to find out causes for failure.

Gearbox failure analysis can help provide and guide suggestions on gearbox maintenance and support gearbox design optimization and devise new models that better adapt to the environment and market.

Learn about the background materials and site conditions of the failed pieces

Observe with the naked eyes or a low-magnification magnifier to determine the failure source and form

Take samples near the failure source to test the mechanical properties, metallographic structure, and chemical composition of the samples

According to survey data and test results, determine the cause of failure and provide the corresponding improvement measures

Submit the reviewed report to the customer

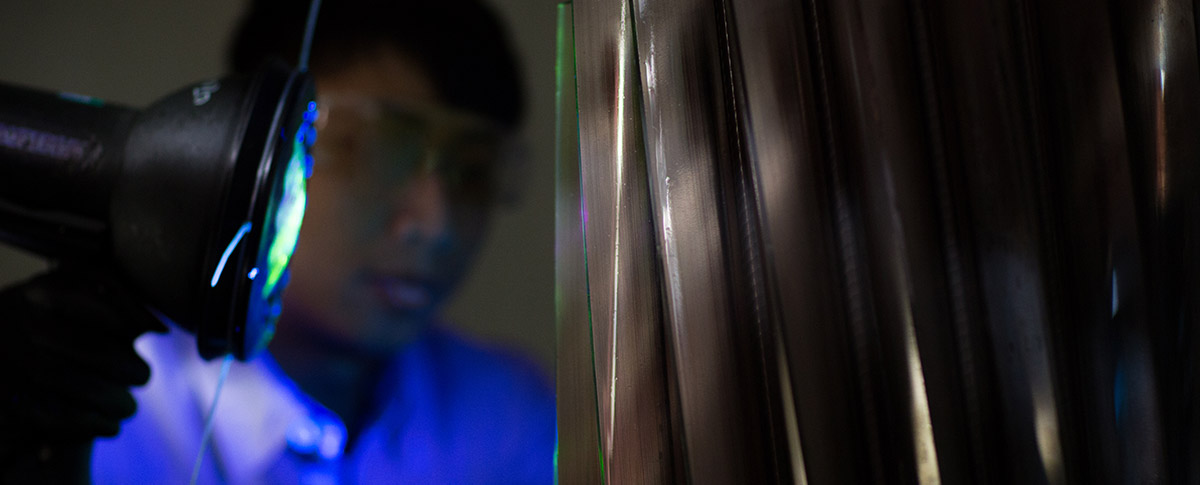

The magnetic powder inspection process for parts